0086 - 18662639130

Precision Cutting, Maximum Efficiency – Every Cut, Perfected.

We Care about Your Sawing Solution

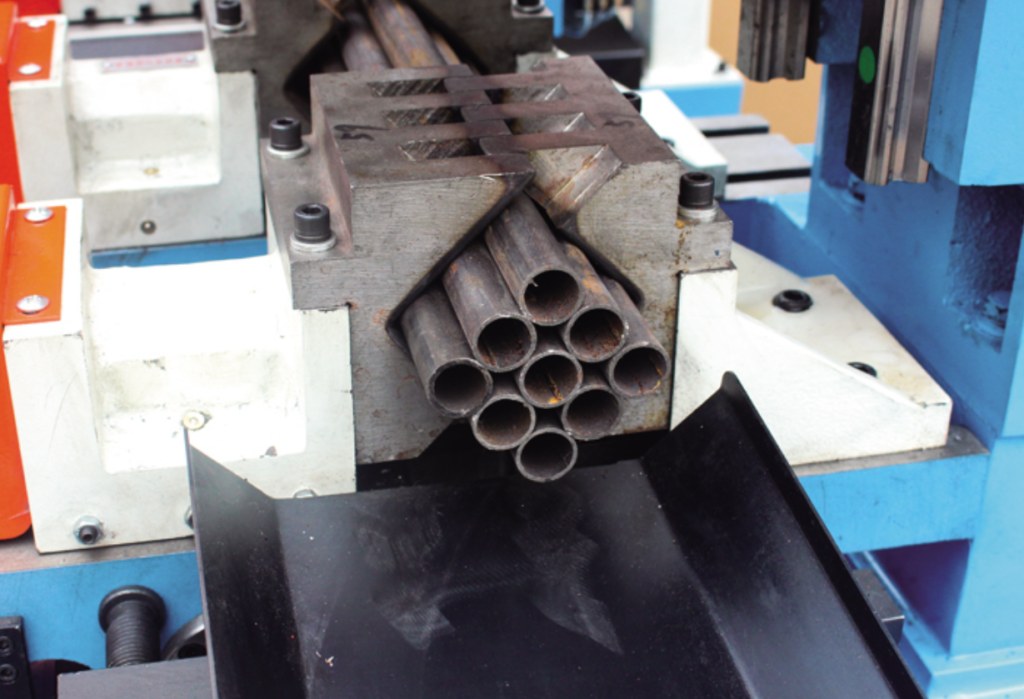

Pipe Sawing Machine with HSS Circular Saw Blade

It is specially designed for cutting carbon steel, stainless steel, galvanized steel and mild steel tubes. Perfect matching for bundles cutting request and high efficiency sawing request. Experience high-performance cutting, longer blade life, and minimal maintenance with our advanced Circular Sawing Machine, ideally for metal pipes and tubes

PNEUMATIC

315B PIPE CUTTNG MACHINE

HYDRAULIC

425Y PIPE CUTTNG MACHINE

CNC SERVO FULL AUTOMATIC TYPE

425CNC PIPE CUTTNG MACHINE

Components that We are Super Proud of

Control Panel

Weinview intelligent HMI 10 inch screen. User-friendly interface with touch screen system. It makes the operation more easily.

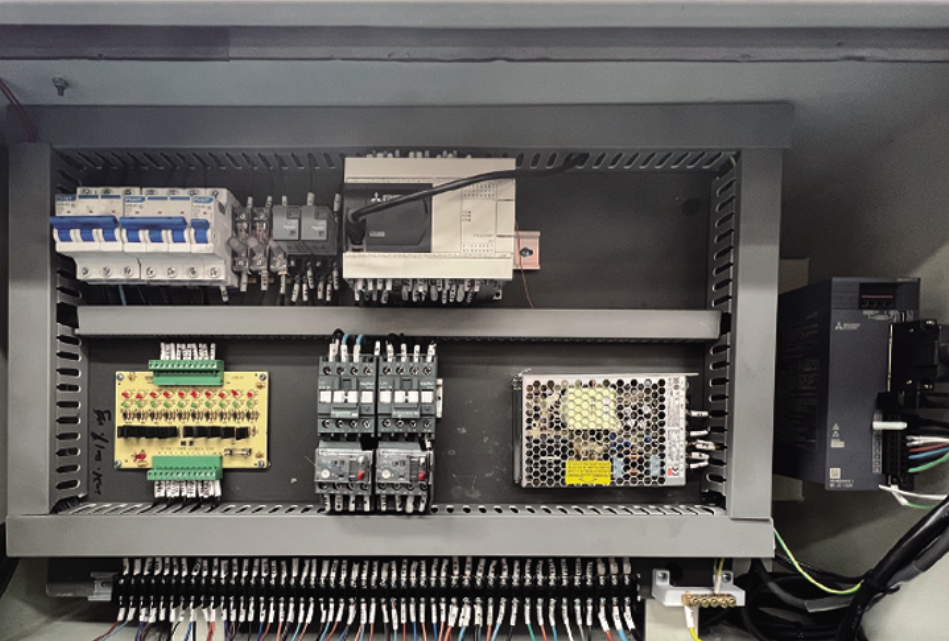

Electrical Panel

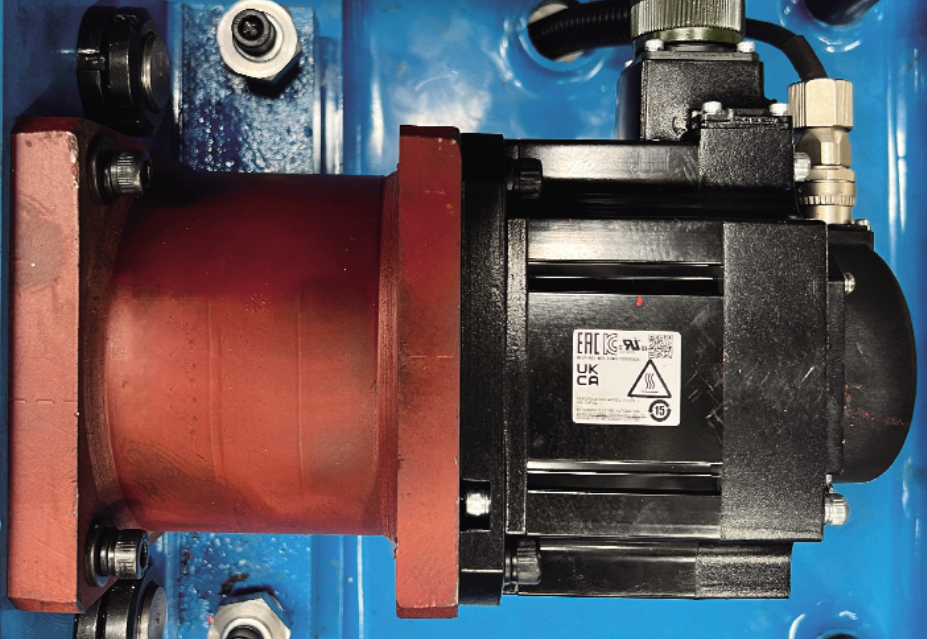

Servo Feeder Motor

Speed Control

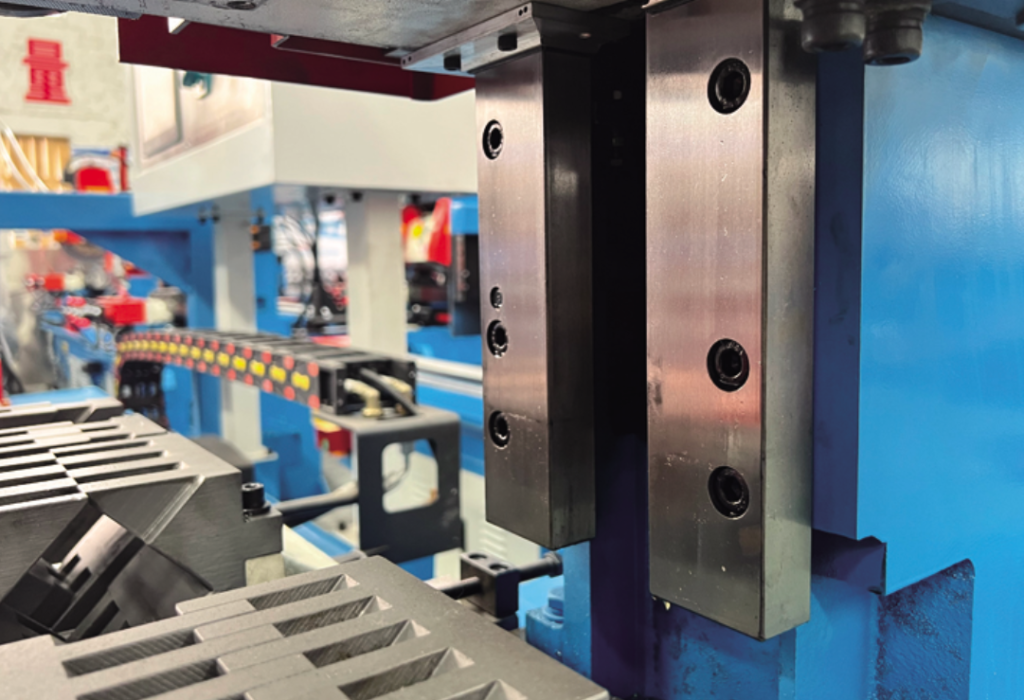

Hard Rail &Gearbox

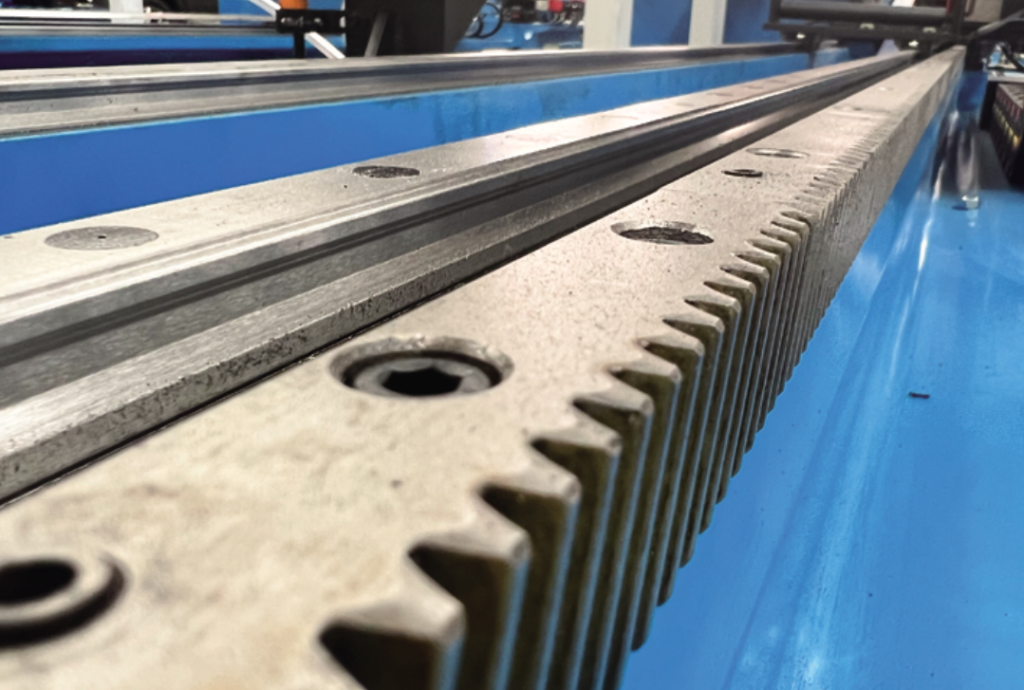

Gear &Guide Rail

Hydraulic Pump

Universal Clamp

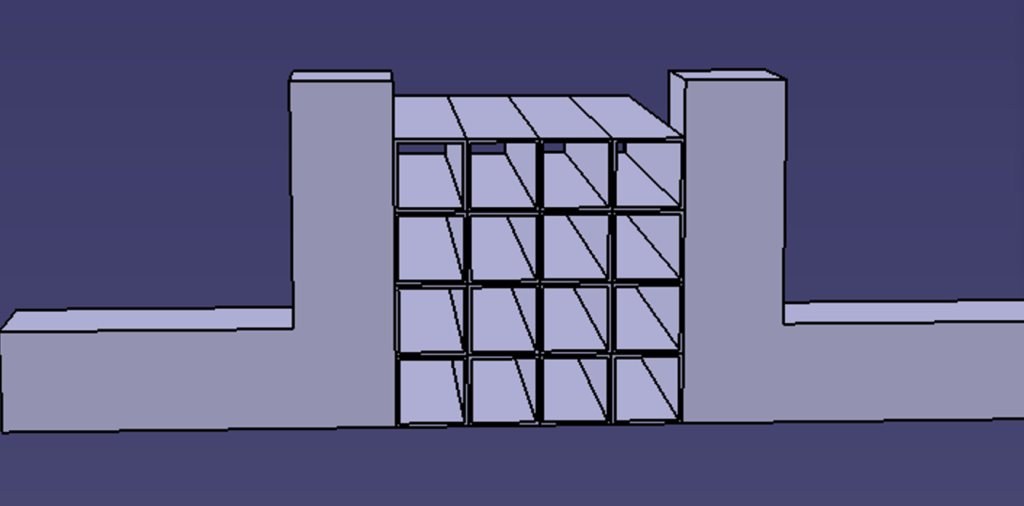

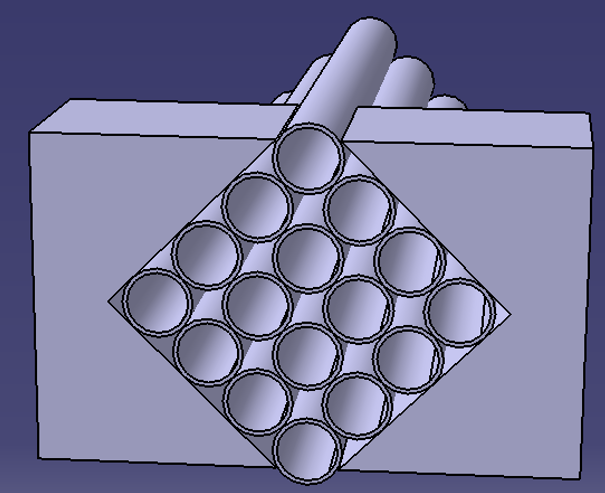

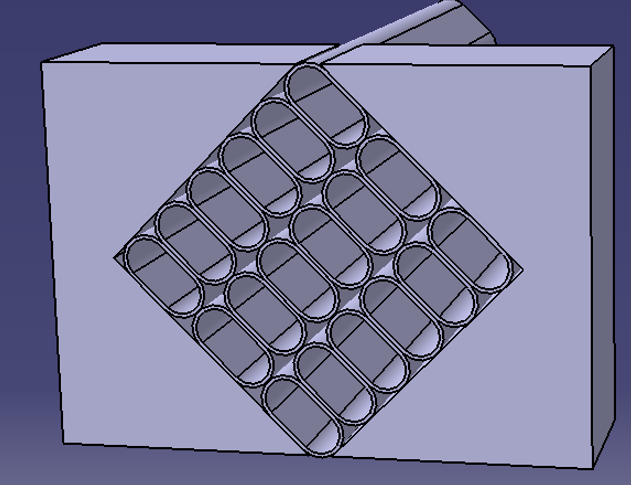

Cut As More As Possible

Drawings to show how the machine cut the tubes by bundles cutting

Horizontal Cutting

425CNC-1500L

425CNC-2000L

425CNC-2500L

425CNC-3000L

Vertical Cutting

425CNC-1000L

425CNC-1500L

425CNC-2000L

425CNC-2500L

425CNC-3000L

Vertical Cutting

425CNC-1000L

425CNC-1500L

425CNC-2000L

425CNC-2500L

425CNC-3000L

Aluminum Sawing Machine with TCT Saw Blade

It is specially designed for cutting aluminum, copper, brass, plastic steel, telfon, other non-ferrous metals tubes and profiles. CNC aluminum tube profile cutting machine delivers precise, high-quality cuts with exceptional speed and efficiency. Ideal for manufacturers, it enhances productivity and ensures smooth, consistent results, whether for small or large production runs. Perfect for improving cutting accuracy in your operations.

PNEUMATIC

500 SEMI AUTO ALUMINUM CUTTING MACHINE

CNC SERVO FULL AUTOMATIC TYPE

550CNC ALUMINUM CUTTNG MACHINE

From Concept to Final Machine

From each item part manufacturing and machining, we have bulks of spare parts for each standard mode to make sure quick delivery time and quality control. Each equipment will be checked and tested before shipping and packed well to delivery to your hand safely and newly. We are welcome to any big order or urgent machine order to be ready in in stock for your on time to help each partner with support and efficiency. Are you ready to get high performance-cost machines?

Frequently Asked Questions

Can’t find the answer you’re looking for? Reach out to our customer support team.

What is a pipe sawing machine?

A pipe sawing machine is an industrial tool designed for cutting metal pipes accurately and efficiently. It uses a rotating saw blade to cut through a variety of materials, such as steel, stainless steel, and other metals, with precision. This machine is widely used in construction, plumbing, and manufacturing industries where large quantities of pipes need to be processed.

What types of pipes can the sawing machine cut?

Our pipe sawing machines can cut a wide range of pipes, including carbon steel, stainless steel, aluminum, and other metal alloys. Whether your pipes are round, square, or rectangular, we have the right solution to meet your cutting needs with high precision and efficiency.

What is the maximum pipe size the machine can handle?

The maximum pipe size depends on the specific model of the pipe sawing machine. Our machines can handle pipes ranging from small diameter sizes (e.g., 10mm) to larger diameter pipes (up to 500mm or more), depending on the machine configuration and the cutting blade used.

How easy is it to maintain the sawing machine?

Our pipe sawing machines are designed for low maintenance and ease of use. Regular maintenance includes keeping the machine clean, checking the blade for wear, and ensuring the motor is running smoothly. Detailed maintenance instructions are provided with each machine, and we offer technical support to help with any concerns.

How long does it take to receive the sawing machine after ordering?

We understand the importance of timely delivery. Once you place an order, the typical lead time for production is 7-10 days and shipping is around 7-30 days, depending on the model, order volume and country. We prioritize fast delivery and can offer expedited shipping options for urgent requirements.

Do you offer customized solutions for specific cutting needs?

Yes, we offer OEM (Original Equipment Manufacturer) services and can customize pipe sawing machines to suit specific requirements. Whether you need modifications in cutting capacity, automation features, or pipe handling systems, our team of engineers will work with you to develop a tailored solution that meets your needs.

Do you provide aftersales support for the sawing machine?

Yes, we offer comprehensive aftersales support for all our pipe sawing machines. Our team provides technical assistance, troubleshooting, and maintenance guidance to ensure your machine operates smoothly. We also offer spare parts availability and support for any repair needs, ensuring minimal downtime for your production.

Is machine installation and setup included in your service?

Yes, we provide machine installation and setup services for our customers. Our team can either guide you remotely or send a technician to your location (depending on your geographical region) to assist with the proper installation, calibration, and testing of the machine. We ensure everything is set up correctly for optimal performance before you begin production.

Do you offer training for operating the sawing machine?

Yes, we offer comprehensive training for your team to ensure safe and efficient operation of the pipe sawing machine. Training can be provided onsite or remotely, depending on your preference. We cover all aspects, including machine operation, maintenance, safety procedures, and troubleshooting. Our goal is to make sure your staff is fully confident in using the machine to its maximum potential.

We'd like to work with You

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 12 hours and help you select the right machine model you need.

0086 186 6263 9130

Company

Suzhou Osvik Science Technology Co., Ltd

Address

No.75, Rd Zhenbei, Leyu Town, Zhangjiagang 215621, Jiangsu, China